Corrosion resistance >>

Home > Corrosion resistance

Corrosion resistance

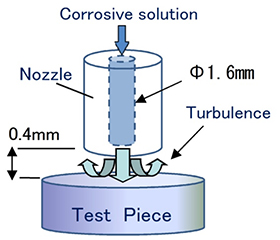

Erosion-corrosion resistance

Erosion corrosion is the phenomenon of decreacing wall thickness in plumbing components.

The typical case of this phenomenon can be found in bending portions of plumbing such as elbows and tees.

NEXTBRASS has achieved excellent erosion corrosion resistance in brass by adding Tin.

Please see result of the accelerated test as follows.

| Test Method | |

|---|---|

|

|

C49355 Wrought products

C49355 Wrought products

C89720 Casting products

C89720 Casting products

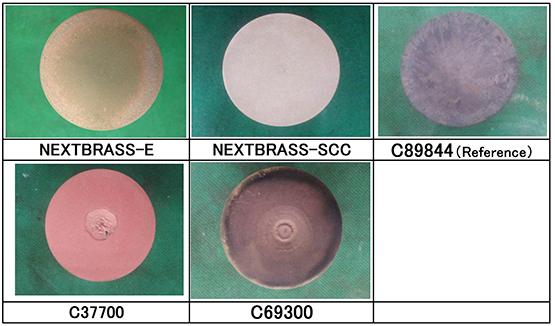

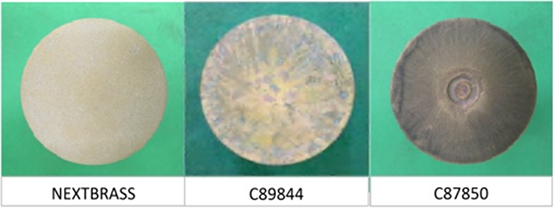

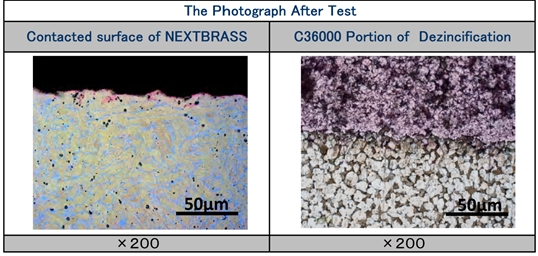

Dezincification resistance

NEXTBRASS also has achieved excellent dezicification resistance.

The result of test was less than 200 μm.

Please see result of the accelerated test as follows.

| Test Method : According to ISO6509-1981 | |

| C49355 Wrought products | C89720 Casting products |

|---|---|

|

|

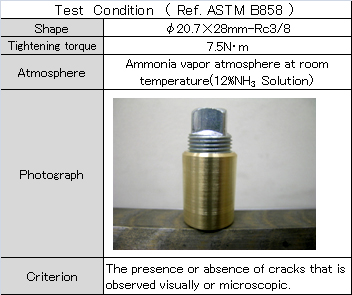

Susceptibility to Stress corrosion cracking

|

| The taper screw combination as shown in the photograph. It's tighten constant torque and be exposed ammonia atmosphere. Then we checked the presence or absence of cracks that is observed visually or microscopic at the specific time. |

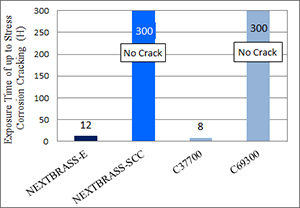

| <TEST RESULT> C49355 Wrought products |

|

| Extruded rod for forging of NEXTBRASS has excellent resistance to stress corrosion cracking than common brass. |

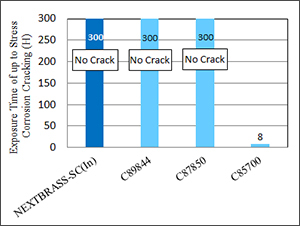

| C89720 Casting products |

|

| Compared with C85700 (CAC203) which cracked in 8 hours. there is no cracking after 312 hours in any NEXTBRASS. |